QUALITY AND PRICE MEET

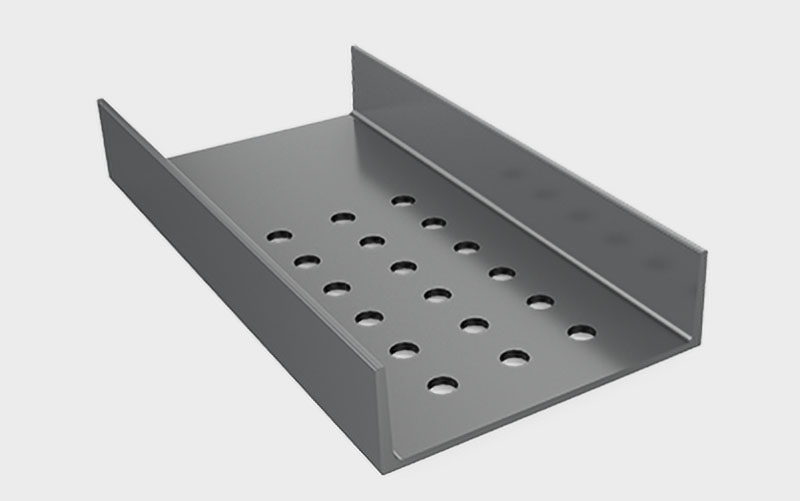

Round, square tubes,

rectangles, special sections,

open profiles

Cutting head

2D/3D

Tubes and profiles up to

28 kg/m

of weight

Tube processing

from 20 to 230

mm in diameter

MACHINE DETAILS

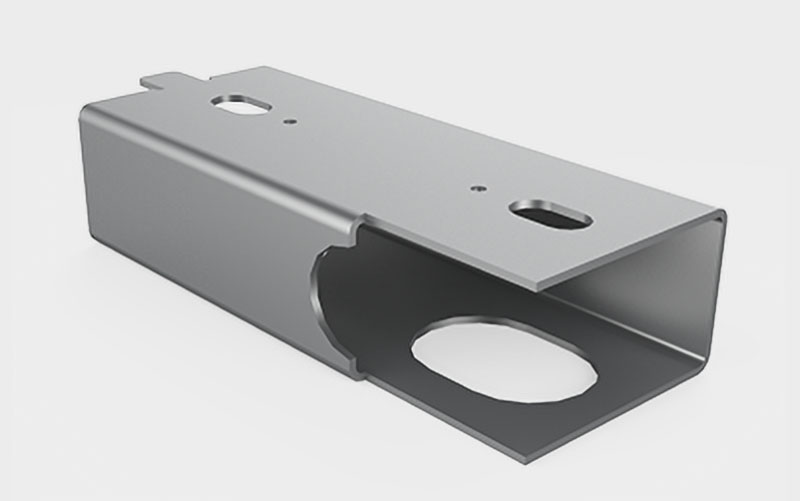

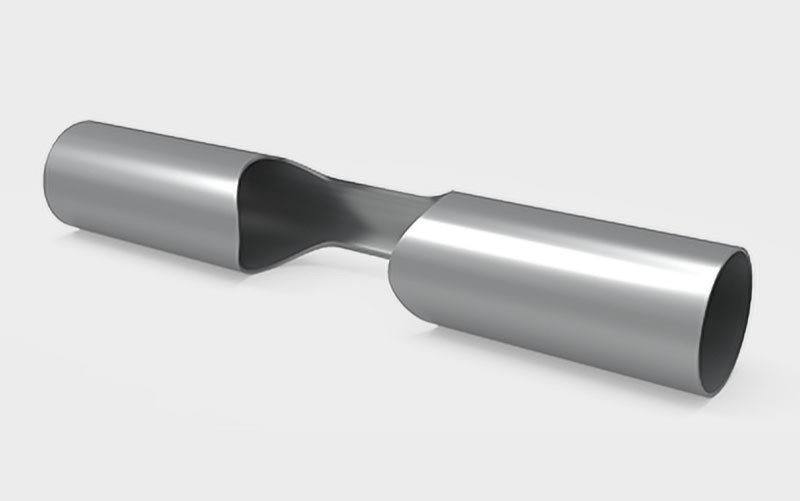

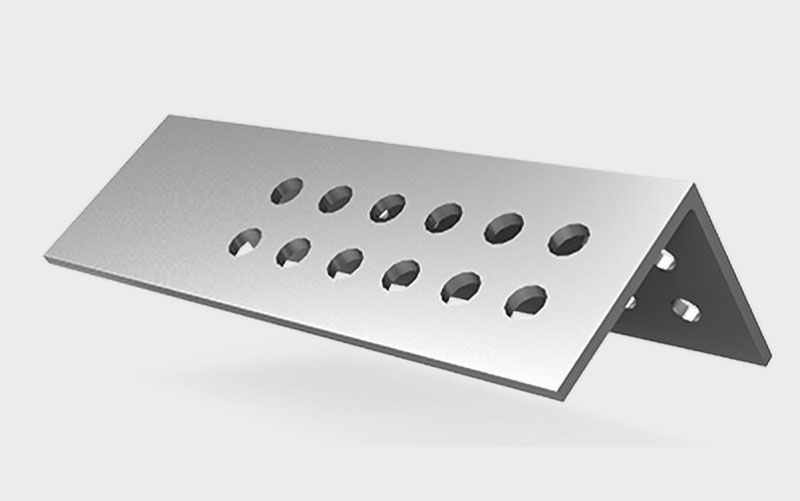

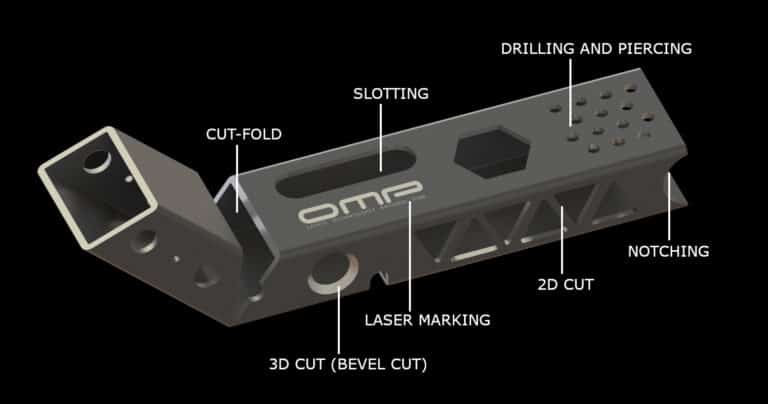

SAMPLING EXAMPLES

WORKABLE PROFILES

Endless laser cutting possibilities for any application!

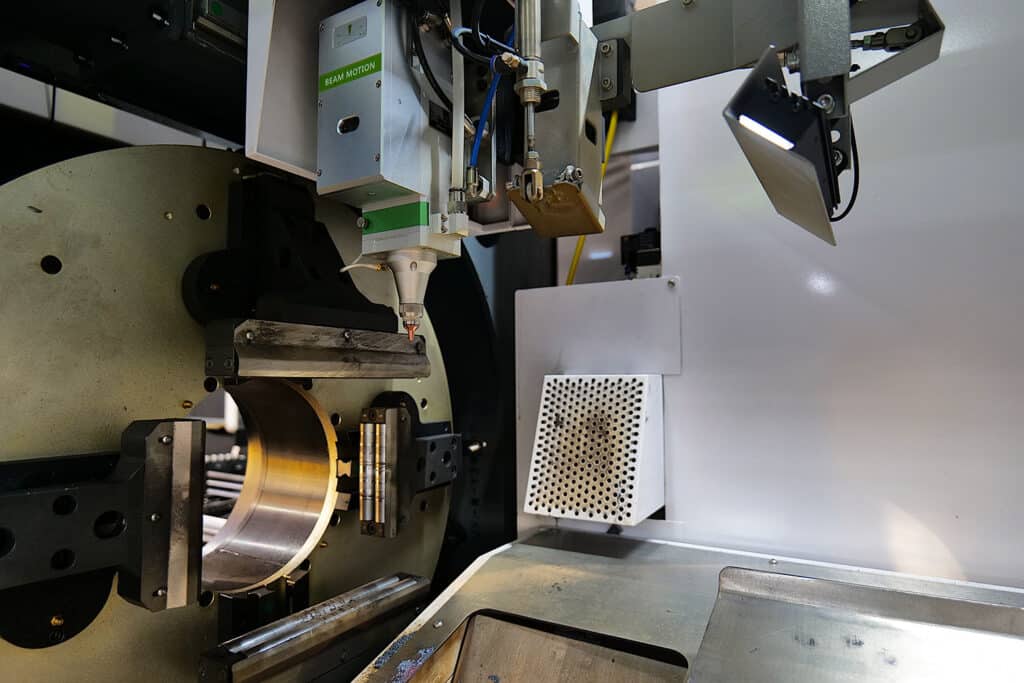

The 3D cutting head offers a wide range of laser cutting processes on the tube, on materials such as aluminium, iron, steel, light alloys and highly reflective materials.

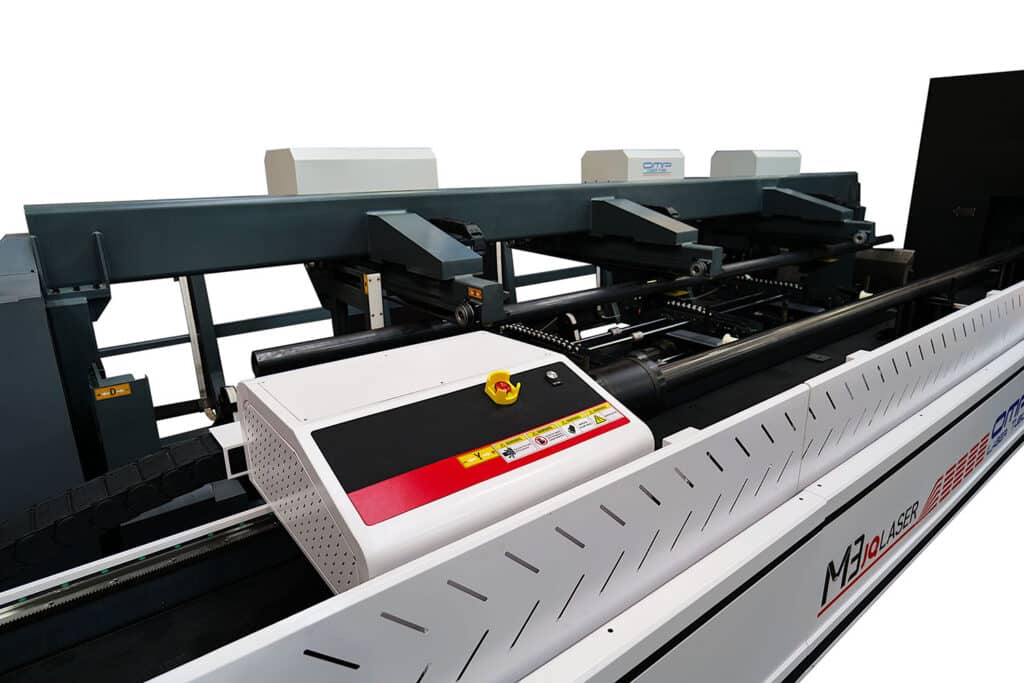

M3 2D/3D

The series of machines with OMP tube laser technology is enriched with a new model, the M3 tube laser, with the aim of offering a versatile and functional product, with an unrivaled quality-price ratio.

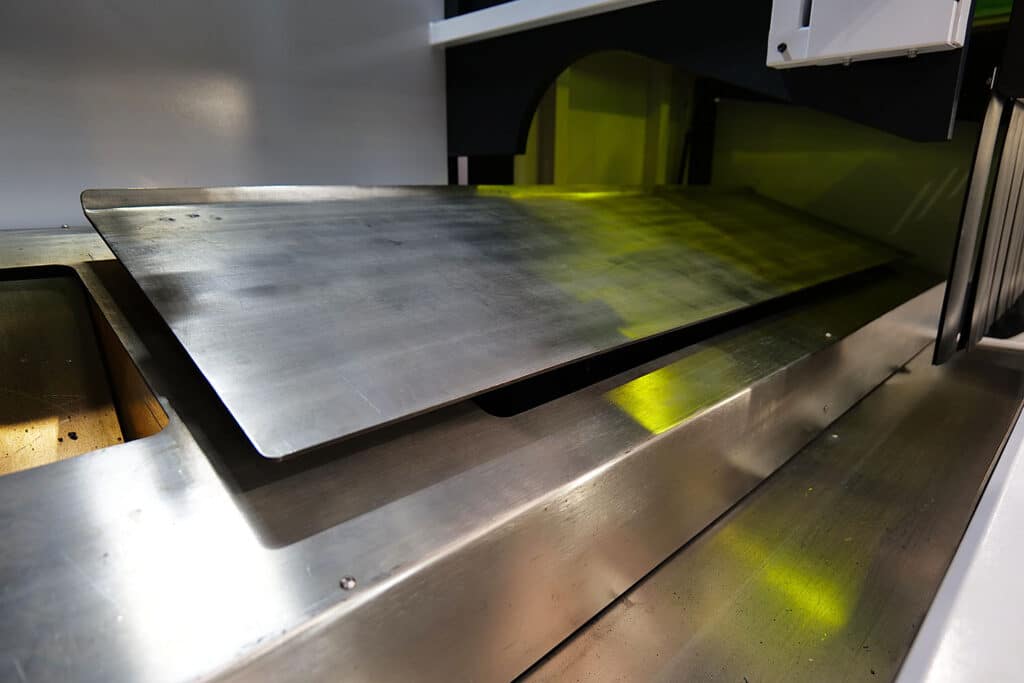

Characterized by a linear and compact design, the M3 tube laser is designed for processing open tubes and profiles from 20 mm to 230 mm in diameter and bar load lengths up to 6300 mm, for cutting carbon steel tubes, stainless steel pipes, aluminum alloy pipes and copper pipes. 3000w source.

The tube laser M3 uses TubesT software.

Equipped with pneumatic locking chucks, with pressure regulation, the clamping action can be completed in less than 3 seconds.

RayTools 2D/3D cutting head.

The Z axis is equipped with a capacitive height adjuster. Laser head with autofocus that significantly improves piercing efficiency on thick pipes.

The machine uses Yaskawa servomotors and Shimpo gearboxes to optimize axis control. Basket loader for bundles of tubes, which acts as a storage tank to avoid machine downtime.

| Technical information M3 2D/3D | |

| Workable diameters | |

| Round tube mm | Min Ø20 Max Ø230 |

| Square tube mm | Inscribed at Ø230 |

| Rectangular tube mm | Inscribed at Ø230 |

| Maximum tube weight | 28 Kg / Meter |

| Loading – Unloading | |

| Loading length mm |

Min 4.000 Max 6.300

|

| Round, square and rectangle tubes Open profiles and special sections |

By bundle – Individually by hand |

| Magazine basket capacity | 2000 Kg; |

| Unloading mm | 2.000 (optional 4000) |

| Laser cut | |

|

Laser source

|

Raycus 3kw

|

| Head type | RayTools 2D/3D |

|

General

|

|

|

Machining precision mm

|

± 0.1 / 200 |

| Workable materials | Mild Steel | Stainless Steel | Aluminum | Copper | Brass |

|

X and Y axis positioning speed

|

±0.05/1000mm |

| Max spindle rotation speed | 120 r/min |

| Tube waste | 110 mm (depending on the tube it may be different) |

| Total installed power | 37 Kw |

| Machine dimensions | 10.675 mm × 3.785 mm × 2.500 mm |

| Laser power | 3.000 W |

| Machine power supply | 400V/50 Hz |