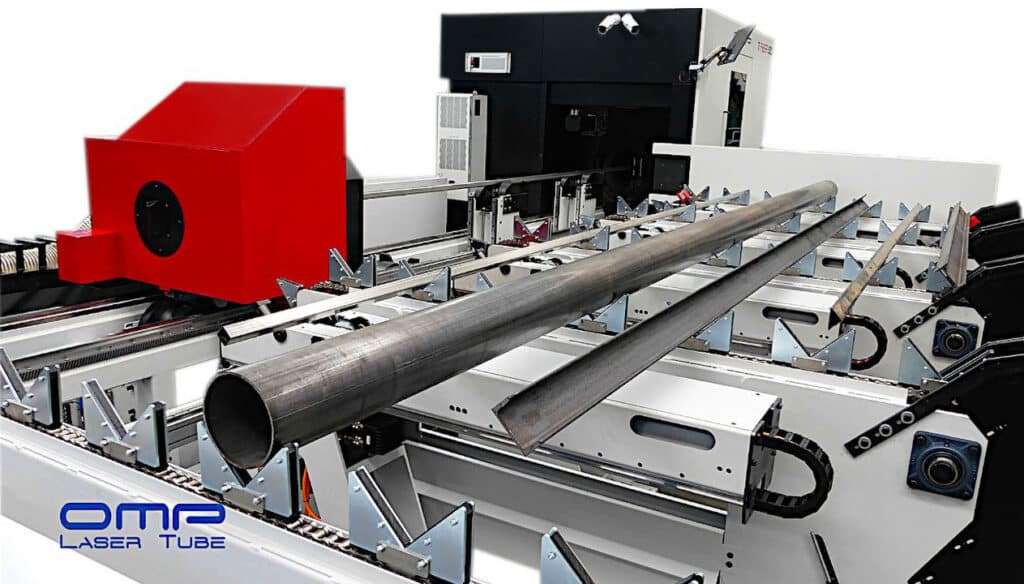

THE MOST ADVANCED MACHINE FOR LASER CUTTING OF TUBES AND PROFILES

Round tubes, square,

rectangles, special sections,

open profiles

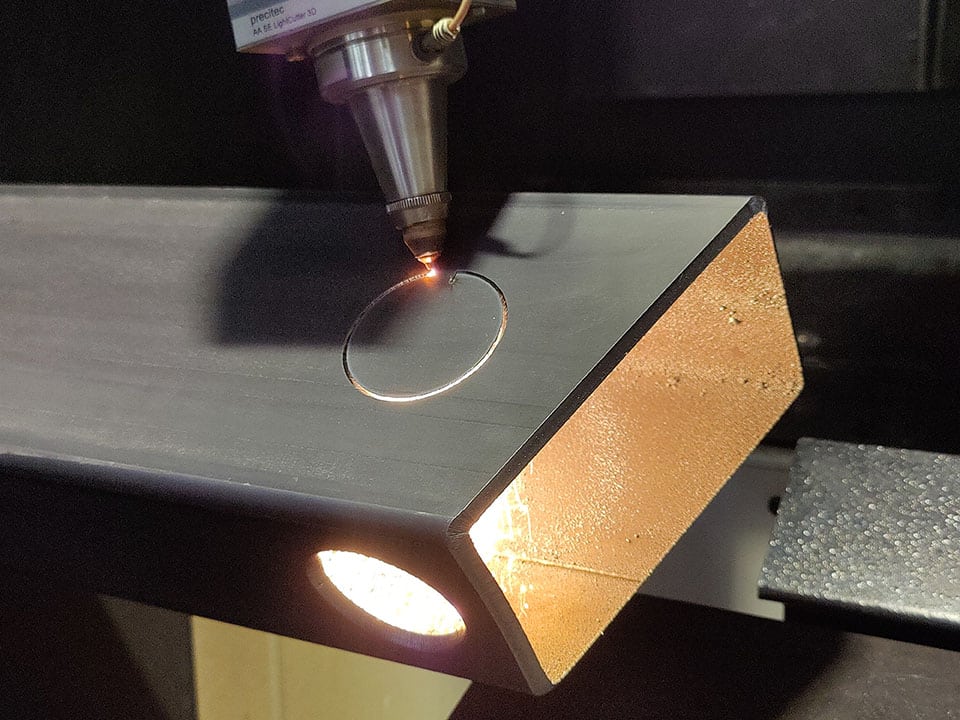

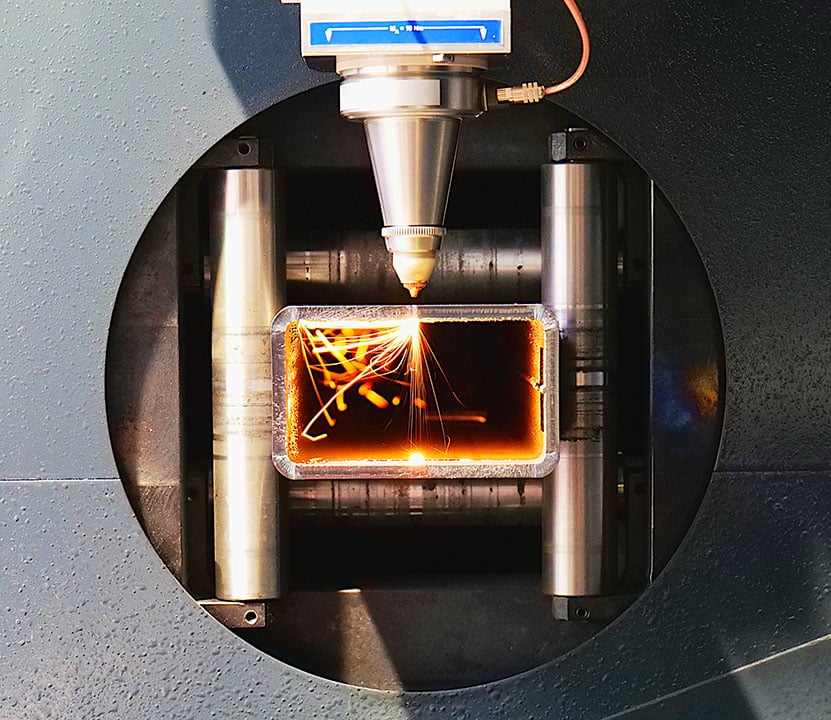

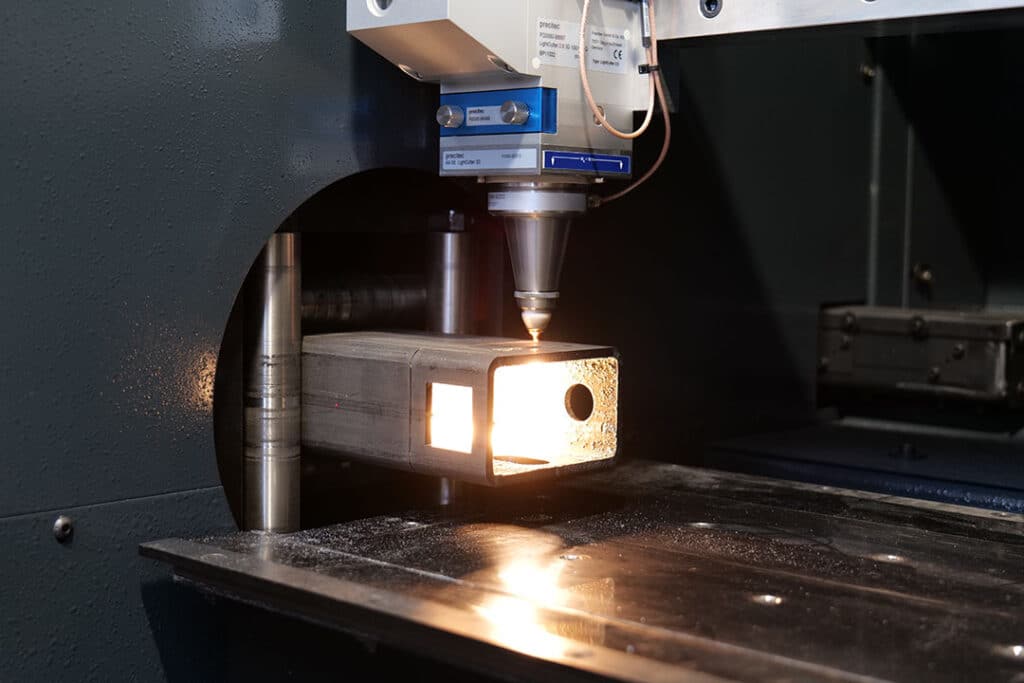

Cutting head

2D/3D

Tubes and profiles up to

36 kg/m

in weight

Tube cutting

from 20 to 220

mm in diameter

MACHINE DETAILS

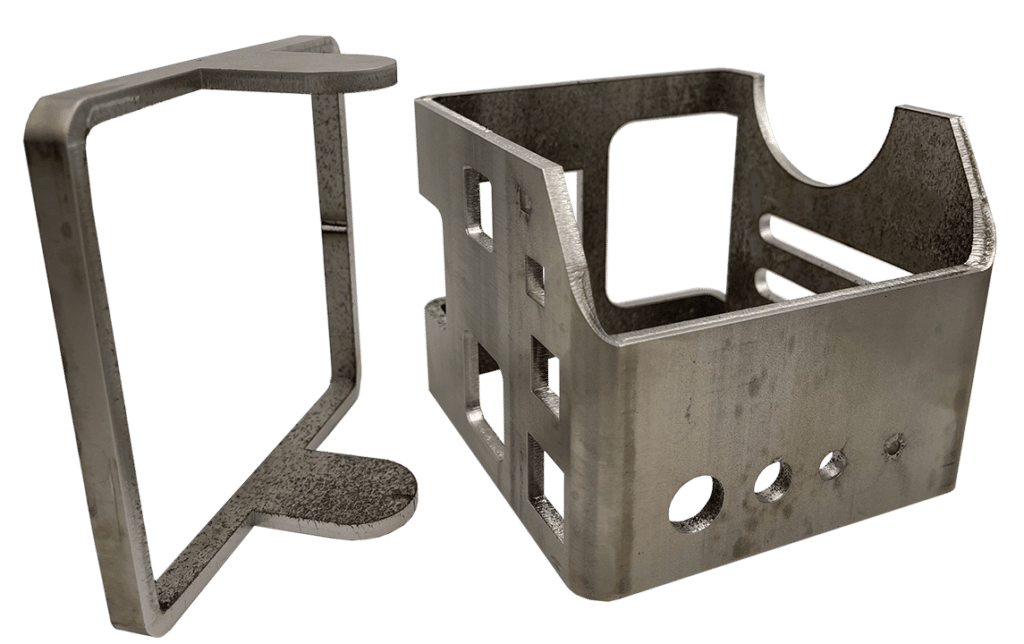

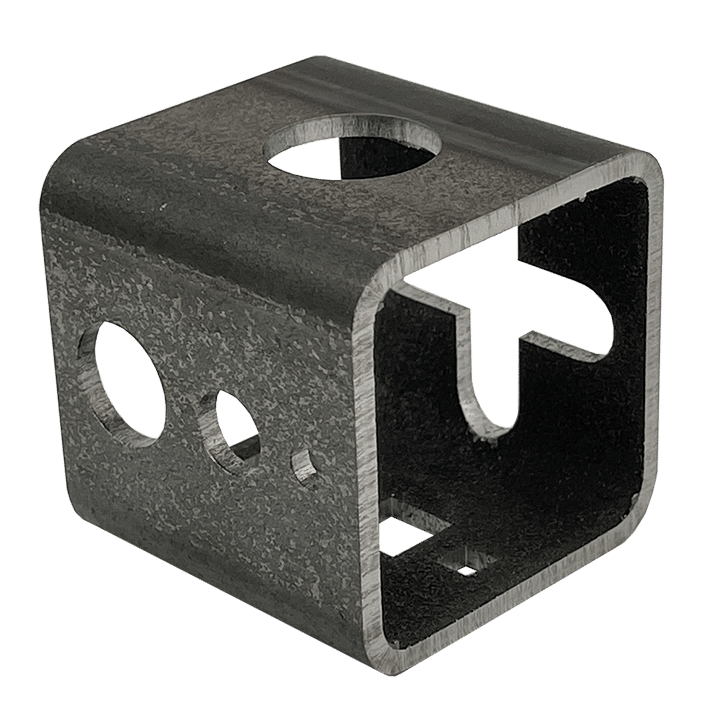

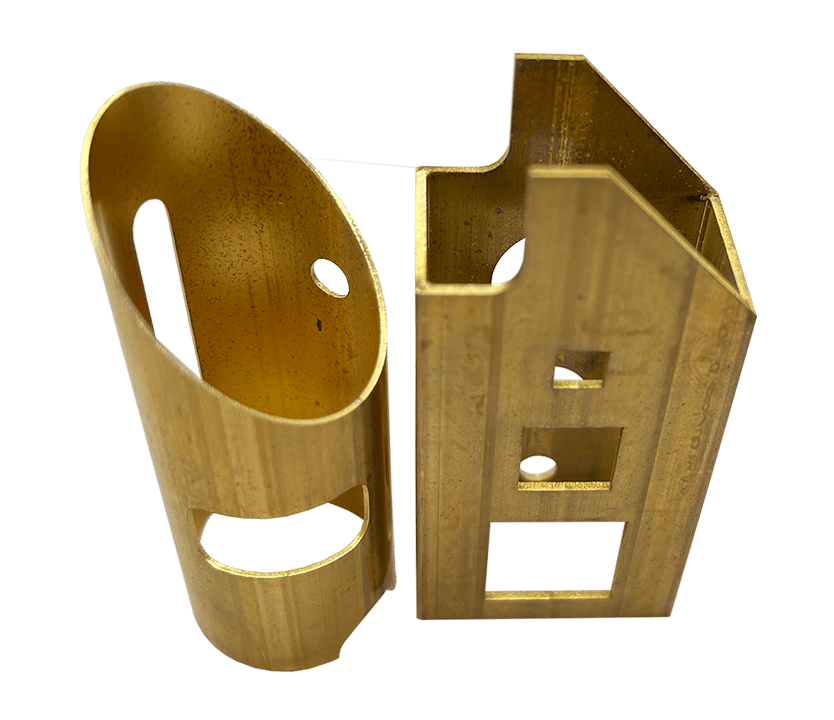

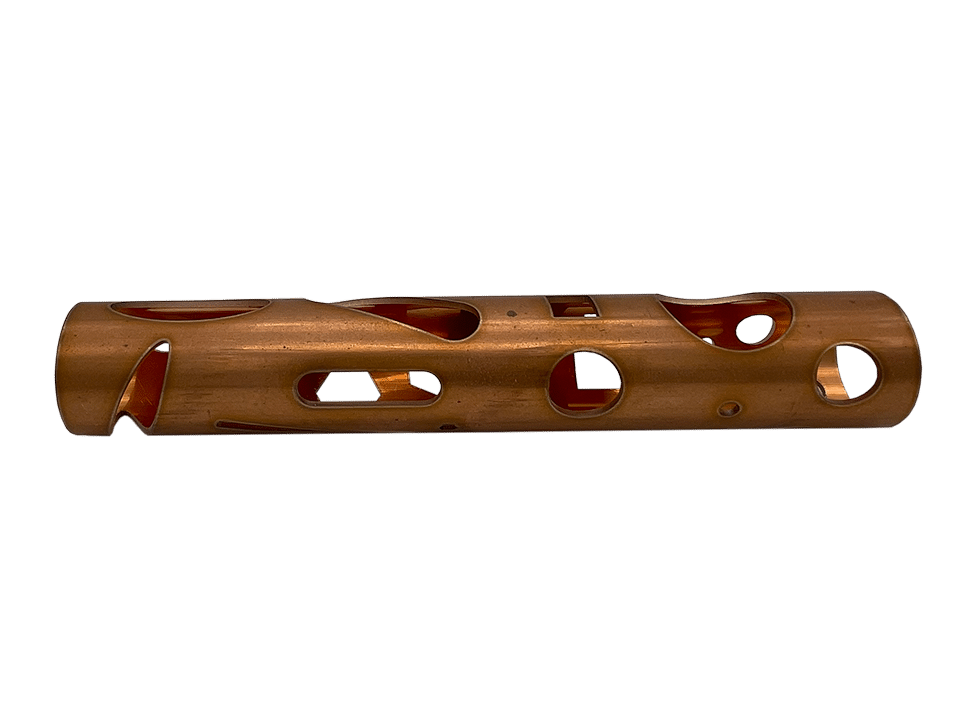

SAMPLING EXAMPLES

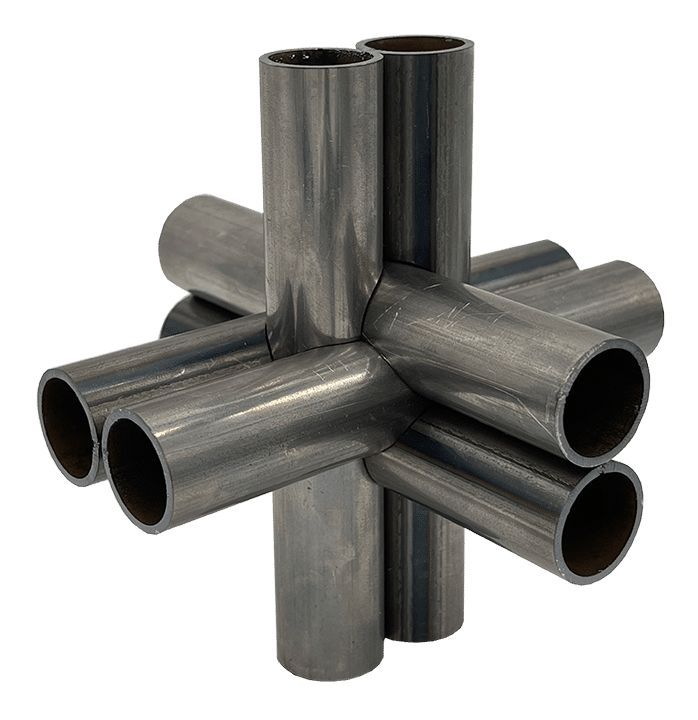

WORKABLE PROFILES

Endless laser cutting possibilities for any application!

The 3D cutting head offers a wide range of laser cutting processes on the tube, on materials such as aluminium, iron, steel, light alloys and highly reflective materials.

TF220 2D/3D

5-axis tube laser, fully automatic, designed for maximum productivity in processing tubes from 20 to 220mm in diameter and bar loading lengths from 6 to 12 meters.

TF220 2D/3D offers excellent versatility of use in the processing of tubes and profiles with the most varied types of materials and thicknesses.

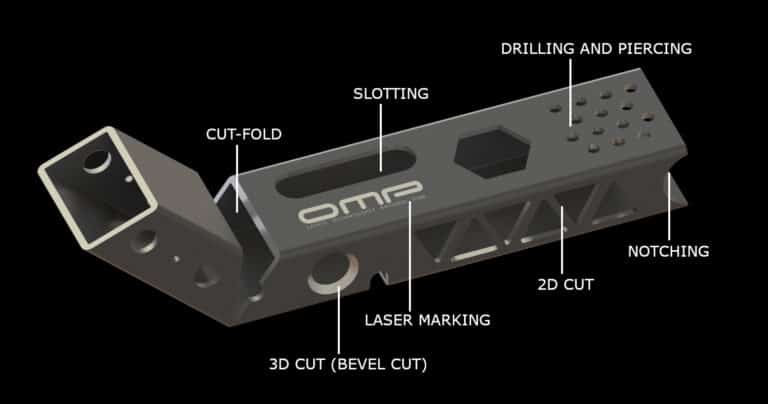

In addition to straight and bevel cutting, it creates holes and slots, markings and engravings, tongue-and-groove joints, flaring, chamfering on sections of round, square and rectangular tubes, special boxed and elliptical profiles, open profiles such as UPN, IPE beams and corners, carbon steel, stainless steel, aluminum alloys and high-reflective materials.

Using an advanced tracking and control system, the laser head can maintain a constant distance from the tube and adapt to curves, corners and other complex shapes. Fiber laser source with power from 1 to 3 kW, others on request based on the thicknesses to be cut.

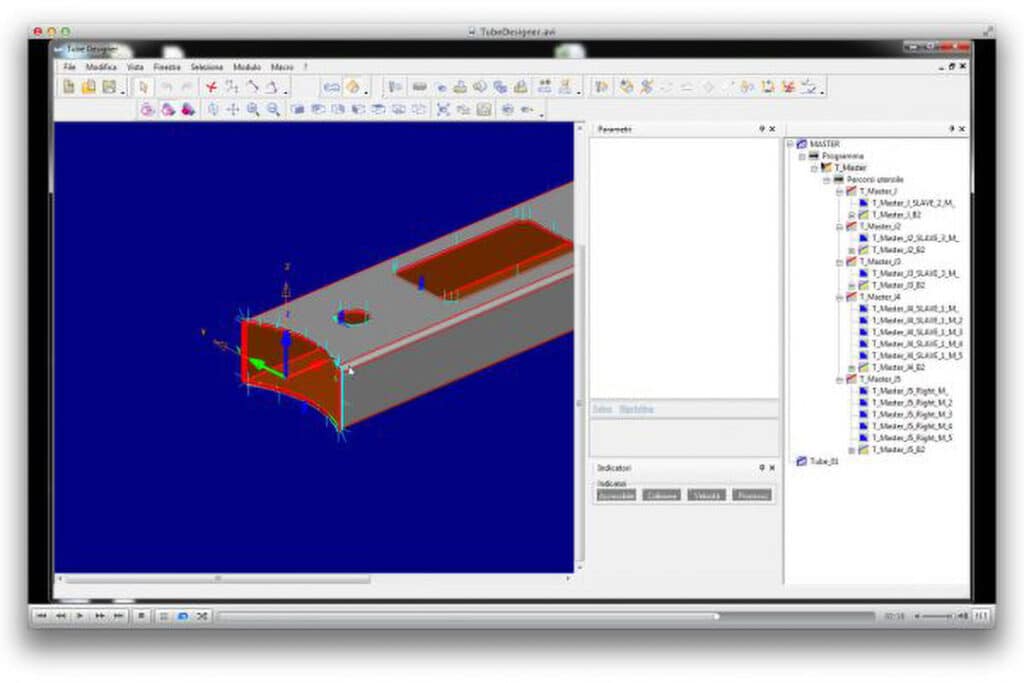

All phases of the programming process are managed by Almacam Tube, CAD-CAM software for cutting tubes and profiles.

It combines working power with high cutting quality even on large thicknesses, the high speed and maximum precision resulting from the linear drive technology maximize the potential of the machine.

With the bundle loader you can work independently, you can produce from bundles or load one or a few bars at a time.

Optimal management of special and/or open profiles.

Standard 4 meter unloading, to unload short or long pieces, separating the scraps.

From the welding reader to remote cameras to the customization of loading and unloading, we put our solutions at your disposal to maximize your productivity.

The compact dimensions of the tube laser and an intuitive user interface guarantee exceptional results even for the most inexperienced operators.

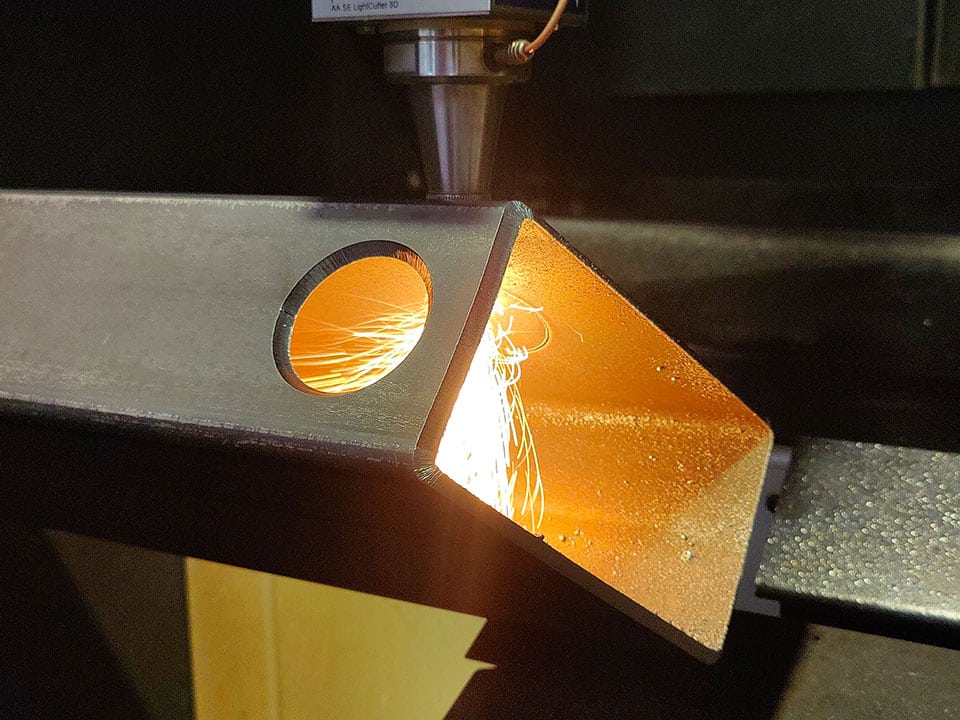

3D CUTTING TECHNOLOGY

The 3D laser head allows the inclination of the cutting head which allows you to achieve high productivity with the possibility of carrying out work on the thickness, such as caulking or countersinking of holes, and is able to work on three-dimensional pieces with complex geometries. This technology frees the designer from the classic concept of mechanical processing, leaving him free to develop innovative ideas and be able to cut the most complex geometric shapes.

| Technical information TF220 2D/3D | |

| Workable diameters | |

| Round tube mm | Min Ø20 Max Ø220 |

| Square tube mm | Min 20×20 Max 160×160 |

| Rectangular tube mm | Min 25×20 Max 200 x 100 |

| Open profiles mm | Inscribed at Ø220 |

| Maximum pipe weight | 36 Kg / Meter |

| Loading – Unloading | |

| Loader |

Bundle tubes– Floor – Combined

|

|

Minimum and maximum loadable length mm

|

Min 2.500 Max 7.000 (others on request) |

| Unloading length mm | 4.000 to 8.000 (others on request) |

| Laser cut | |

|

Laser source

|

Fibra 1 – 3 KW (others on request) |

| Head type | Precitec 2D/3D (others on request) |

|

General

|

|

| Machining precision mm | ± 0.05 / 200 |

| Workable materials |

Mild Steel | Stainless Steel | Aluminum | Copper | Brass

|

|

Min/Max processing speed mm

|

150/20.000 |

|

X and Y axis positioning speed mm/min

|

80.000 |

| Total power absorbed | 33 KW |

| Machine dimensions mm | 14.700×5.000×2.600 |

| Machine weight | 15.100 kg |